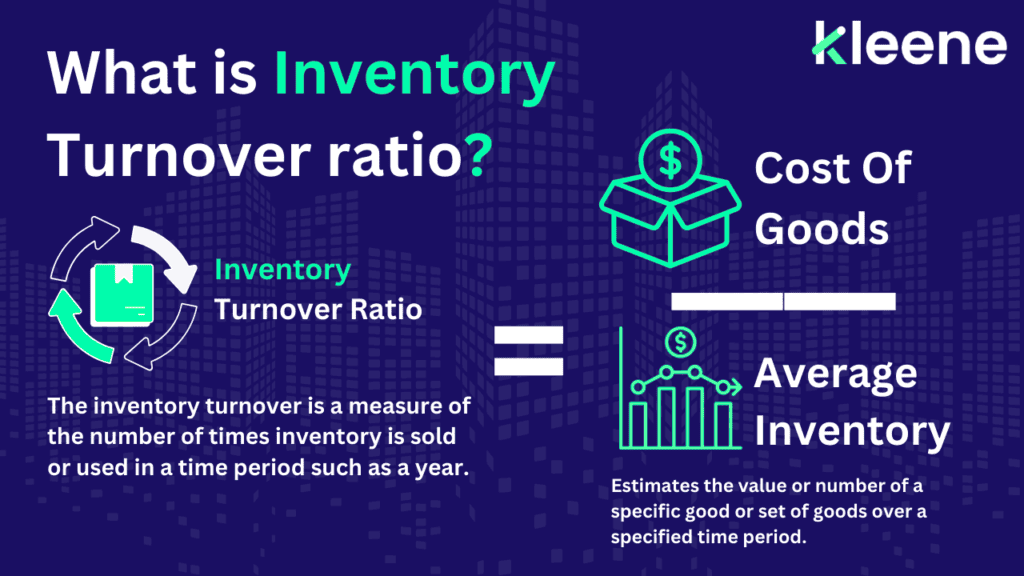

In today’s fast-paced business environment, optimising your inventory turnover ratio is essential for maintaining a competitive edge. The ratio measures how efficiently a company manages its inventory by calculating how often inventory is sold and replaced over a given period. It is a crucial metric for understanding your business’s efficiency and profitability.

Understanding Inventory Turnover Ratio

The inventory turnover ratio is a key performance indicator (KPI) that reveals how well a company manages its inventory. This ratio helps businesses determine how frequently they are able to sell and restock their inventory within a specific timeframe. A high ratio indicates strong sales and efficient inventory management, while a low ratio may signal overstocking or sales issues. Calculating and analysing your inventory turnover provides valuable insights into operational effectiveness and financial health.

You may also like: What is inventory control: 10 Strategies

How to Calculate Inventory Turnover Ratio

To calculate the ratio, use the following formula:

Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory

Here’s a step-by-step guide:

- Calculate Cost of Goods Sold (COGS): This is the total cost incurred to produce or purchase the goods that were sold during a specific period. It includes all direct costs associated with the production of goods.

- Determine Average Inventory: This is the average amount of inventory held over the same period. It is typically calculated by adding the beginning inventory and ending inventory for the period and dividing by two.

- Apply the Formula: Divide the COGS by the average inventory to get the inventory turnoverd.

By accurately calculating this ratio, businesses can gain insights into how efficiently they are managing their stock. It helps identify trends, spot potential issues, and make informed decisions to optimise inventory levels.

You may also like: Unlocking Success: The 10 Most Powerful Inventory Formulas

The Limitations of ERP Systems

Enterprise Resource Planning (ERP) systems are commonly used for managing various business processes, including inventory. However, these systems often come with limitations that can affect the accuracy of your inventory turnover ratio. Some of the common limitations include:

- Limited Reporting Capabilities: ERP systems may not provide the detailed and custom reports needed to analyse the inventory turnover ratio effectively.

- Complex Setup: Setting up ERP systems can be time-consuming and complex, requiring significant resources and expertise.

- Data Accuracy Issues: If the ERP system is not correctly configured or if data entry is inaccurate, it can lead to unreliable calculations of the inventory turnover ratio.

Due to these limitations, businesses may find it challenging to obtain accurate and actionable insights from their ERP systems alone.

Integrating Data into a Data Warehouse

Integrating data into a data warehouse can address the limitations of ERP systems and provide more comprehensive insights. A data warehouse consolidates data from multiple sources, offering a unified view that enhances the accuracy of your inventory turnover ratio calculations. Here’s how it benefits inventory management:

- Enhanced Accuracy: Data warehouses provide a centralised repository of accurate data, reducing the risk of errors associated with ERP systems.

- Improved Forecasting: With consolidated data, businesses can generate more accurate forecasts, helping to align inventory levels with actual demand.

- Custom Reporting: Data warehouses support detailed and custom reporting, allowing for in-depth analysis of the inventory turnover ratio and other key metrics.

By integrating data into a data warehouse, businesses can achieve more reliable results and make better-informed decisions.

Challenges with Black-Box Solutions

Black-box solutions are often used to add functionality on top of ERP systems, but they come with their own set of challenges. These solutions may offer advanced features but can fall short in several areas:

- Integration Issues: Black-box solutions may not seamlessly integrate with your existing technology stack, sales channels, or other systems.

- Adaptability: These solutions may not be tailored to your specific business model, leading to potential inefficiencies and discrepancies in the inventory turnover ratio.

- Limited Customisation: Reports and analytics provided by black-box solutions are often generic and may not address your unique business needs.

For a truly effective inventory management system, it is essential to choose a solution that integrates well with your existing systems and is adaptable to your specific requirements.

Tailored Solutions for Better Inventory Management

A tailored solution is crucial for effective inventory management. Unlike standalone solutions or black-box systems, a customised solution offers several advantages:

Benefits of a Tailored Solution

- Customised Reports: Tailored solutions provide reports that are specific to your business needs. This ensures a deeper understanding of the inventory turnover ratio and other key performance indicators.

- Seamless Integration: Custom solutions are designed to integrate with your existing technology stack and sales channels, providing a comprehensive view of inventory management.

- Enhanced Accuracy: By addressing the specific needs of your business, tailored solutions reduce the risk of inaccuracies and provide actionable insights into your inventory turnover.

With a customised solution, businesses can optimise inventory management more effectively and improve overall operational efficiency.

5 Proven Strategies to Optimise Your Inventory Turnover Ratio

- Improve Inventory Forecasting: Utilise advanced analytics and data from a data warehouse to enhance forecasting accuracy. By predicting demand more precisely, you can reduce both overstock and stockouts, leading to a better inventory turnover.

- Streamline Supply Chain Management: Enhance your supply chain processes to ensure timely restocking of inventory. Efficient supply chain management reduces lead times and aligns inventory levels with demand, boosting your inventory turnover.

- Implement Just-in-Time (JIT) Inventory: Adopt a JIT inventory system to minimise excess stock and reduce holding costs. JIT focuses on ordering inventory only as needed, which helps improve your inventory turnover ratio by keeping stock levels lean.

- Analyse and Adjust Pricing Strategies: Regularly review and adjust pricing strategies to reflect market demand and competition. Competitive pricing can drive higher sales volumes, positively impacting your inventory turnover ratio.

- Enhance Inventory Visibility and Tracking: Use technology to improve inventory tracking and visibility across all sales channels. Real-time data on inventory levels enables more informed decision-making and increases the efficiency of your inventory turnover ratio.

Key Takeaways

Optimising your inventory turnover ratio is vital for improving business efficiency and profitability. While ERP systems offer a range of functionalities, they have limitations in reporting and data accuracy. Integrating data into a data warehouse provides a more comprehensive view, ensuring accurate calculations of your inventory turnover ratio and effective forecasting.

Tailored solutions are preferable to black-box systems, as they offer better integration with your tech stack and provide customised reports. By focusing on accurate inventory management and leveraging the right tools, businesses can enhance their inventory turnover ratio and overall operational efficiency.

Understanding and optimising your inventory turnover ratio can lead to more informed decisions that drive better performance and profitability.

Using Kleene for Retail Inventory Management

Kleene is a leading AI-powered inventory management solution trusted by data-driven companies worldwide. With its advanced demand forecasting capabilities and comprehensive data analysis tools, Kleene gives retailers everything they need to confidently optimise inventory levels, reduce costs and improve operational efficiency. It’s a must-have platform for retail inventory management.

With Kleene’s predictive analytics and actionable insights, retailers can find new opportunities for growth around every corner. AI-powered retail inventory management offers immense potential for retailers to find ways to optimise their supply chain operations and drive enhanced customer satisfaction. In adopting a few best practices and leveraging a platform like Kleene, retailers can stay ahead of the curve.

Download our free e-book on how CFOs can master working capital in retail.

You may also like:

7 Powerful Tips for Small Business Inventory Management to Maximise Efficiency

7 Key Reasons Why a Tailored Inventory Management App Outperforms ERP Systems

The Ultimate Guide to Inventory Management Software: Top Solutions for 2024

7 Powerful Insights on What is Inventory in Accounting

Frequently Searched Questions About Inventory Turnover Ratio

- How to Calculate Inventory Turnover Ratio?

- The inventory turnover ratio is calculated by dividing the cost of goods sold (COGS) by the average inventory. This metric helps businesses understand how often they sell and restock their inventory.

- What is the Inventory Turnover Ratio Equation?

- The formula for the inventory turnover ratio is: Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory.

- How Do You Calculate Stock Turn?

- Stock turn, or inventory turnover ratio, is calculated similarly by dividing COGS by the average inventory. This helps measure the efficiency of inventory management.

- What is the Formula for Inventory Days?

- The formula for calculating inventory days is: Inventory Days = 365 / Inventory Turnover Ratio. This metric shows how many days, on average, inventory remains before it is sold.

- What is the Difference Between Inventory Turnover and Stock Turn?

- Inventory turnover and stock turn are the same metrics, used interchangeably to measure how often inventory is sold and replaced over a period.

- Why is Inventory Turnover Ratio Important?

- The inventory turnover ratio is important because it indicates how efficiently a company manages its inventory. A high ratio suggests strong sales and efficient inventory management, while a low ratio may indicate overstocking or slow-moving inventory.

- What Does a High Inventory Turnover Ratio Indicate?

- A high inventory turnover ratio indicates that a company is selling and replenishing its inventory quickly, suggesting efficient inventory management and strong sales performance.

- What Does a Low Inventory Turnover Ratio Indicate?

- A low inventory turnover ratio may indicate overstocking, slow-moving inventory, or issues with sales performance. It suggests that inventory is not being sold quickly enough.

- How Often Should Businesses Calculate Their Inventory Turnover Ratio?

- Businesses should calculate their inventory turnover ratio regularly, such as monthly, quarterly, or annually, to monitor inventory performance and make informed management decisions.

- What is a Good Inventory Turnover Ratio?

- A good inventory turnover ratio varies by industry. Generally, a higher ratio is better, but the ideal ratio depends on the specific business context and industry standards.

- How Does Inventory Turnover Ratio Affect Cash Flow?

- A higher inventory turnover ratio can improve cash flow by reducing the amount of capital tied up in inventory. This means that more cash is available for other business needs.