Introduction

In today’s fast-paced and competitive business environment, effective inventory tracking management is crucial for maintaining operational efficiency and staying ahead of the competition. Traditional ERP (Enterprise Resource Planning) systems, while powerful for managing various business functions, often fall short when it comes to comprehensive and detailed inventory management. This article will explore seven distinct ways in which dedicated inventory tracking management solutions offer superior functionality and reporting compared to ERP systems. Additionally, we will examine how integrating data into a data warehouse can enhance accuracy, streamline forecasting, and provide a more efficient alternative to complex ERP setups.

1. Enhanced Reporting Capabilities

ERP systems often provide limited reporting features when it comes to inventory management. The reports generated can be too generic and may lack the specific details needed for effective inventory control. In contrast, dedicated inventory tracking management solutions offer advanced reporting capabilities tailored to your business needs. Custom reports can provide detailed insights into inventory levels, sales trends, and other critical metrics, ensuring that you have the data necessary for informed decision-making. By using these tailored reporting tools, businesses can achieve a deeper understanding of their inventory and make strategic adjustments with confidence.

2. Greater Integration Flexibility

One of the limitations of traditional ERP systems is their often rigid structure when it comes to integration. Many ERP solutions require extensive configuration to work with existing tech stacks and sales channels, which can be both time-consuming and costly. Inventory tracking management solutions that utilise data warehousing offer greater flexibility and seamless integration with various systems. This enhanced integration capability ensures that all components of your business technology work together harmoniously, providing a more cohesive view of inventory data and improving overall efficiency.

3. Improved Forecast Accuracy

Accurate forecasting is crucial for effective inventory management, yet ERP systems can sometimes struggle to provide precise forecasts. The data used for forecasting in ERP systems may be incomplete or not well-integrated, leading to inaccuracies. By integrating data into a data warehouse, businesses can centralise and harmonise information from multiple sources, leading to more accurate and reliable forecasts. Enhanced forecasting capabilities help businesses maintain optimal inventory levels, reduce the risk of stockouts or overstock situations, and better align inventory with market demand.

You may also like: Efficient Stock Control System: 5 Ways to Enhancing Inventory Management (copy)

4. Faster Implementation and Lower Costs

Implementing and configuring an ERP system can be a lengthy and expensive process, often involving significant investments in both time and money. This setup process can delay the availability of accurate inventory data and insights. In contrast, inventory tracking management solutions that leverage data warehousing can offer a quicker and more cost-effective implementation. These solutions can bypass many of the complexities associated with ERP setups, allowing businesses to start benefiting from enhanced inventory management and reporting sooner, and at a lower overall cost.

5. Seamless Adaptation to Business Models

ERP systems are often designed with a one-size-fits-all approach, which may not always align with the specific needs of your business. Black-box solutions that enhance ERP systems often fail to integrate seamlessly with your unique business model and operational requirements. Dedicated inventory tracking management solutions, on the other hand, are designed to adapt to your specific business model. This tailored approach ensures that the solution meets your precise needs and integrates effectively with your existing systems, providing a more customised and effective inventory management experience.

6. Reduction of Data Silos

Data silos can arise when different systems and processes within an organisation operate in isolation, leading to inefficiencies and incomplete information. Many ERP systems and black-box solutions exacerbate this problem by creating separate data repositories that are not fully integrated. Inventory tracking management solutions that use data warehousing address this issue by centralising and integrating data from various sources. This comprehensive data integration helps to eliminate data silos, providing a unified view of inventory and enabling more effective management and decision-making.

7. Customised and Detailed Inventory Insights

Generic ERP systems and standalone solutions may not always provide the level of detail required for comprehensive inventory management. Businesses often need more customised and detailed insights to manage complex inventory scenarios effectively. Tailored inventory tracking management solutions offer the ability to generate highly customised reports and analyses that are specific to your business needs. This level of detail ensures that you have the insights necessary to make informed decisions, optimise inventory levels, and enhance overall operational performance.

AI Enhancement in Inventory Tracking Systems

Artificial Intelligence (AI) has revolutionised inventory tracking systems by introducing advanced analytical capabilities and automation. AI-powered inventory tracking solutions can analyse vast amounts of data at unprecedented speeds, uncovering patterns and trends that traditional systems might miss. Here’s how AI enhances inventory tracking systems:

- Predictive Analytics: AI uses historical data and machine learning algorithms to predict future inventory needs with high accuracy. By identifying patterns in sales data, seasonal trends, and market conditions, AI can forecast demand more effectively than traditional methods. This helps businesses optimise stock levels, reduce excess inventory, and prevent stockouts.

- Automated Replenishment: AI-driven systems can automate the replenishment process by predicting when inventory levels will fall below a predefined threshold. This automation reduces manual intervention, speeds up the ordering process, and ensures that stock levels are always aligned with demand.

- Dynamic Pricing: AI can analyse market trends, competitor pricing, and customer behaviour to suggest optimal pricing strategies. Dynamic pricing helps businesses maximise revenue and maintain competitive advantage by adjusting prices in real-time based on demand and market conditions.

- Supply Chain Optimization: AI enhances supply chain management by analysing data across the entire supply chain to identify bottlenecks, optimise routes, and improve supplier performance. This optimisation leads to more efficient inventory management and reduced operational costs.

The Role of Demand Forecasting

Effective demand forecasting is crucial for successful inventory management and is greatly enhanced by AI technologies. Here’s how demand forecasting contributes to better inventory management:

- Accurate Predictions: Demand forecasting uses historical sales data, market trends, and other relevant factors to predict future demand for products. Accurate forecasts help businesses plan their inventory levels more effectively, ensuring they can meet customer demand without overstocking or understocking.

- Trend Analysis: Forecasting tools analyse trends and seasonality to provide insights into how demand fluctuates over time. This analysis helps businesses prepare for peak seasons, promotional periods, and market changes, allowing for more informed inventory decisions.

- Scenario Planning: Advanced forecasting tools can simulate various scenarios, such as changes in market conditions or supply chain disruptions. By preparing for different scenarios, businesses can develop contingency plans and adjust their inventory strategies proactively.

- Improved Decision-Making: Reliable demand forecasting provides businesses with actionable insights that support better decision-making. By understanding future demand patterns, businesses can make informed choices about purchasing, production, and distribution.

Conclusion

In summary, while ERP systems provide a broad range of functionalities, they often fall short in delivering comprehensive inventory tracking management. By leveraging data warehousing, businesses can overcome these limitations, achieving more accurate forecasts and streamlined inventory management. Tailored inventory tracking management solutions offer significant benefits, including enhanced reporting, greater integration flexibility, and reduced data silos, making them a superior choice for businesses aiming to optimise their inventory strategies.

Adopting these advanced solutions enables businesses to enhance operational efficiency, lower costs, and achieve superior results in inventory management. As the business landscape evolves, leveraging the right tools and strategies for inventory tracking management will be crucial for maintaining a competitive edge and driving long-term success.

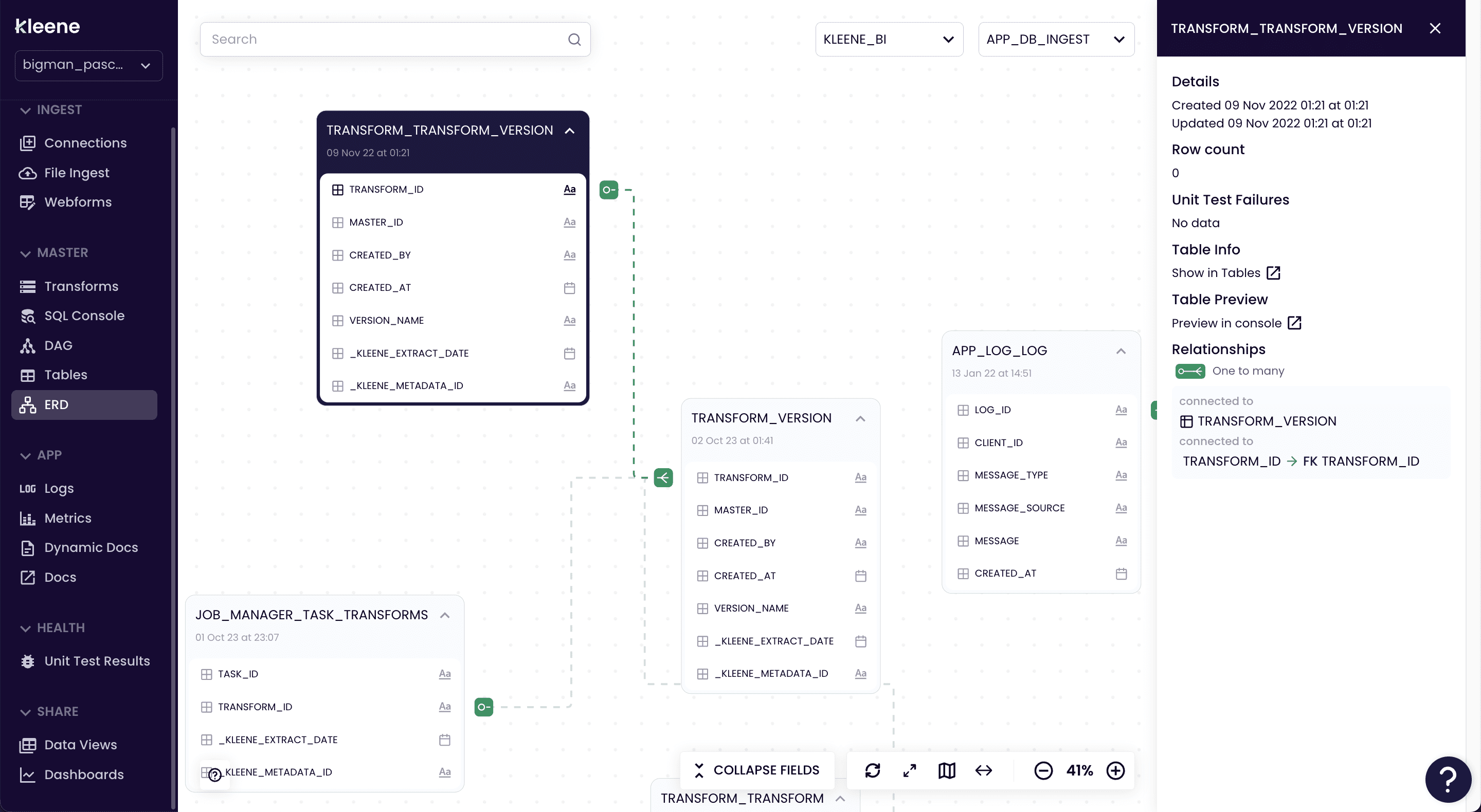

Using Kleene for Retail Inventory Management

Kleene is a leading AI-powered inventory management solution trusted by data-driven companies worldwide. With its advanced demand forecasting capabilities and comprehensive data analysis tools, Kleene gives retailers everything they need to confidently optimise inventory levels, reduce costs and improve operational efficiency. It’s a must-have platform for retail inventory management.

With Kleene’s predictive analytics and actionable insights, retailers can find new opportunities for growth around every corner. AI-powered retail inventory management offers immense potential for retailers to find ways to optimise their supply chain operations and drive enhanced customer satisfaction. In adopting a few best practices and leveraging a platform like Kleene, retailers can stay ahead of the curve.

Download our free e-book on how CFOs can master working capital in retail.

You may also like:

7 Powerful Tips for Small Business Inventory Management to Maximise Efficiency

Unlocking Success: The 10 Most Powerful Inventory Formulas

Boost Your Inventory Turnover Ratio with These 5 Proven Strategies

7 Powerful Insights on What is Inventory in Accounting

Frequently Asked Questions

To further clarify the importance of effective inventory tracking management, here are some frequently asked questions:

What is inventory management?

Inventory management involves overseeing and controlling a company’s inventory to ensure that stock levels are optimal, costs are minimised, and sales opportunities are maximised. It encompasses processes such as ordering, storing, and using inventory.

You may also like: What is inventory control: 10 Strategies

What is the definition of an inventory management system?

An inventory management system is a software tool designed to track inventory levels, orders, sales, and deliveries. It helps businesses manage their stock efficiently, ensuring that the right products are available at the right time.

What is inventory tracking management?

Inventory tracking management refers to the process of monitoring and managing inventory levels to ensure accuracy and efficiency. It involves tracking inventory from the moment it is ordered until it is sold, helping businesses maintain optimal stock levels and reduce costs.

How does inventory tracking management improve forecasting?

Effective inventory tracking management enhances forecasting by providing accurate and timely data on inventory levels, sales trends, and demand patterns. This data helps businesses make informed decisions and adjust their inventory strategies to meet market demands.

Why is data warehousing important for inventory management?

Data warehousing is important for inventory management because it centralises and integrates data from various sources, providing a comprehensive view of inventory performance. This integration allows for more accurate analysis and forecasting, improving overall inventory management.