Introduction

Understanding inventory formulas is crucial for any business looking to optimize its stock levels and reduce costs. In this article, we will delve into the most utilized inventory formulas, exploring their applications, benefits, and how they can be improved using AI. Additionally, we will discuss which actions can improve or worsen the accuracy and effectiveness of these formulas.

What Are Inventory Formulas?

Inventory formulas are sets of mathematical calculations used to manage and control inventory levels effectively. These formulas help businesses determine the optimal amount of stock to hold, reorder points, safety stock, and more. By using inventory formulas, businesses can maintain a balance between meeting customer demand and minimizing inventory costs.

Key Inventory Formulas and Their Applications

Economic Order Quantity (EOQ)

The EOQ formula determines the optimal order quantity that minimizes the total cost of inventory, including ordering and holding costs.

Formula: EOQ equals the square root of two times demand rate times ordering cost per order, divided by the holding cost per unit per year.

Improvements:

- Accurate Demand Forecasting: Using precise demand forecasts based on historical data and market trends improves the accuracy of EOQ.

- Reducing Costs: Minimizing ordering and holding costs through better supplier negotiations and efficient warehouse management enhances the EOQ calculation.

- AI Integration: AI can predict demand patterns and optimize order schedules, leading to more accurate and dynamic EOQ values.

Detriments:

- Fluctuating Demand: Significant variations in demand can lead to incorrect EOQ calculations, resulting in either overstocking or stockouts.

- Inconsistent Costs: Changes in ordering or holding costs without corresponding adjustments in the formula can reduce its effectiveness.

Reorder Point (ROP)

The ROP formula calculates the inventory level at which a new order should be placed to avoid stockouts.

Formula: ROP equals average daily demand multiplied by lead time in days.

Improvements:

- Regular Updates: Continuously updating lead times and demand rates based on the latest data ensures ROP accuracy.

- Supplier Performance Monitoring: Keeping track of supplier performance and reliability helps maintain consistent lead times.

- AI Utilization: AI can analyze historical data to predict lead times and demand more accurately, adjusting reorder points in real-time.

Detriments:

- Variable Lead Times: Inconsistent lead times due to unreliable suppliers can lead to premature or delayed reorders.

- Inaccurate Demand Forecasts: Errors in forecasting demand can cause incorrect reorder points, leading to either stockouts or excessive inventory.

Safety Stock Formula

Safety stock is the extra inventory kept to prevent stockouts caused by demand variability or lead time fluctuations.

Formula: Safety Stock equals the desired service level in standard deviations multiplied by the standard deviation of demand, multiplied by the square root of lead time in days.

Improvements:

- Accurate Variability Measurement: Precisely measuring demand variability and lead time fluctuations improves safety stock calculations.

- Adjusting Service Levels: Tailoring service levels based on customer expectations and business goals ensures adequate safety stock.

- AI Enhancements: AI can continuously monitor demand and supply variations, dynamically adjusting safety stock levels to balance service levels and inventory costs.

Detriments:

- Overestimating Variability: Excessively high estimates of demand variability lead to unnecessarily large safety stock levels, tying up capital.

- Inconsistent Lead Times: Fluctuations in lead times can make it challenging to maintain the right safety stock levels.

Average Inventory Formulas

The average inventory formulas calculates the typical amount of inventory held over a specific period.

Formula: Average Inventory equals beginning inventory plus ending inventory, divided by two.

Improvements:

- Regular Audits: Conducting regular inventory audits ensures accurate beginning and ending inventory counts, improving the reliability of average inventory calculations.

- Consistent Tracking: Maintaining consistent sales and inventory tracking systems enhances the accuracy of average inventory figures.

- AI Automation: AI can automate inventory tracking and provide real-time updates, ensuring precise average inventory calculations.

Detriments:

- Inventory Count Discrepancies: Errors or inconsistencies in inventory counts can lead to inaccurate average inventory figures.

- Fluctuating Inventory Levels: Significant changes in inventory levels during the period can distort average inventory calculations, affecting planning and decision-making.

Days Sales of Inventory (DSI)

DSI measures the average number of days it takes to sell the entire inventory.

Formula: DSI equals average inventory divided by cost of goods sold, multiplied by 365.

Improvements:

- Efficient Sales Forecasting: Enhancing sales forecasting accuracy helps maintain optimal inventory levels, improving DSI.

- Reducing Inventory Levels: Streamlining inventory to match sales velocity can reduce DSI, indicating efficient inventory management.

- AI Integration: AI can optimize sales forecasts and inventory management, aligning inventory levels with actual sales patterns to improve DSI.

Detriments:

- Excess Inventory: Holding too much inventory increases DSI, indicating inefficiency.

- Slow-Moving Inventory: Products that do not sell quickly can raise DSI, reflecting poor inventory turnover.

Inventory Turnover Ratio

The inventory turnover ratio indicates how many times inventory is sold and replaced over a period.

Formula: Inventory Turnover Ratio equals cost of goods sold divided by average inventory.

Improvements:

- Increasing Sales: Boosting sales while maintaining or reducing inventory levels improves the turnover ratio.

- Efficient Inventory Management: Implementing efficient inventory management practices, such as just-in-time inventory, enhances turnover rates.

- AI Utilization: AI can optimize inventory levels based on demand forecasts and automate replenishment processes, improving inventory turnover.

Detriments:

- Excess Inventory: Holding too much inventory reduces the turnover ratio, indicating inefficiency.

- Poor Sales Performance: Slow sales can lead to reduced inventory turnover, reflecting poor demand and inventory management.

Gross Margin Return on Investment (GMROI)

GMROI measures the profitability of inventory by comparing the gross margin to the average inventory investment.

Formula: GMROI equals gross margin divided by average inventory cost.

Improvements:

- Better Pricing Strategies: Improving gross margins through strategic pricing enhances GMROI.

- Reducing Inventory Costs: Lowering inventory costs through efficient procurement and management practices boosts GMROI.

- AI Optimization: AI can analyze sales and pricing data to optimize gross margins and inventory investments, ensuring maximum profitability.

Detriments:

- High Inventory Costs: Elevated inventory costs reduce GMROI, indicating inefficiency.

- Low Gross Margins: Poor pricing strategies or high costs of goods sold can negatively impact GMROI.

ABC Analysis

ABC analysis categorizes inventory into three classes based on their importance:

- A: High-value items with low frequency of sales

- B: Moderate-value items with moderate frequency of sales

- C: Low-value items with high frequency of sales

Improvements:

- Regular Reviews: Continuously reviewing and updating inventory classifications based on sales and value data ensures accurate ABC analysis.

- Prioritizing High-Value Items: Focusing management efforts on high-value items (Class A) improves overall inventory control.

- AI-Driven Categorization: AI can dynamically reclassify items based on real-time sales and value data, ensuring accurate prioritization and efficient management.

Detriments:

- Inaccurate Classification: Misclassifying items can lead to inefficient inventory management and misplaced focus.

- Neglecting Lower-Value Items: Ignoring lower-value items (Class C) may result in stockouts for those products, impacting customer satisfaction.

Demand Forecasting

Demand forecasting predicts future customer demand using historical data, helping businesses plan their inventory levels accordingly.

Improvements:

- Comprehensive Data Analysis: Using extensive historical data and considering market trends improves forecast accuracy.

- Regular Updates: Continuously updating forecasts based on the latest data and trends ensures reliability.

- AI Enhancements: AI leverages machine learning algorithms to analyze vast amounts of data and identify patterns, resulting in highly accurate demand forecasts.

Detriments:

- Incomplete Data: Relying on incomplete or inaccurate data leads to poor demand forecasts.

- Ignoring Market Trends: Failing to consider external factors and market trends can reduce forecast accuracy.

Lead Time Formula

The lead time formula calculates the time taken from placing an order to receiving it.

Formula: Lead Time equals order delivery date minus order placement date.

Improvements:

- Supplier Performance Monitoring: Keeping track of supplier performance and reliability ensures consistent lead times.

- Clear Communication: Establishing clear and open communication with suppliers helps ensure timely deliveries.

- AI Prediction: AI can analyze supplier data and predict potential delays, allowing businesses to adjust order schedules proactively.

Detriments:

- Inconsistent Suppliers: Variable supplier performance leads to fluctuating lead times, impacting inventory planning.

- Order Processing Delays: Delays in internal order processing can affect lead time reliability, leading to inventory imbalances.

Improving Inventory Formulas with AI

AI can significantly enhance the accuracy and efficiency of inventory formulas. Here’s how:

Predictive Analytics

AI-driven predictive analytics can improve demand forecasting by analyzing historical data and identifying patterns. This leads to more accurate EOQ, ROP, and safety stock calculations.

Real-Time Data Processing

AI enables real-time data processing, allowing businesses to adjust inventory levels promptly based on current demand and supply conditions.

Automated Decision-Making

AI can automate reorder decisions, ensuring timely restocking and reducing the risk of stockouts or overstocking.

Enhanced Accuracy

Machine learning algorithms can continuously learn and improve from data, enhancing the precision of inventory management formulas.

The Role of AI in Inventory Management

Integration with ERP Systems

AI can integrate seamlessly with ERP systems, enhancing their functionality and overcoming their limitations in reporting and data accuracy.

Comprehensive Data Analysis

AI consolidates data from various sources, providing a holistic view of inventory levels, demand patterns, and supply chain dynamics.

Customization and Flexibility

AI-powered inventory management solutions can be tailored to fit specific business models and requirements, providing customized reports and insights.

Scalability

AI solutions can scale with business growth, handling increasing volumes of data and complexity without compromising performance.

Conclusion

Inventory formulas are vital tools for optimizing inventory levels and improving overall business efficiency. By understanding and applying various inventory formulas, businesses can achieve significant cost savings and operational improvements. Integrating AI into inventory management further enhances these benefits, providing accurate forecasts, real-time data processing, and automated decision-making.

Remember, the key to successful inventory management lies in using the right tools and methods. Inventory formulas, combined with AI-driven solutions, provide a robust framework for optimizing inventory and driving business success.

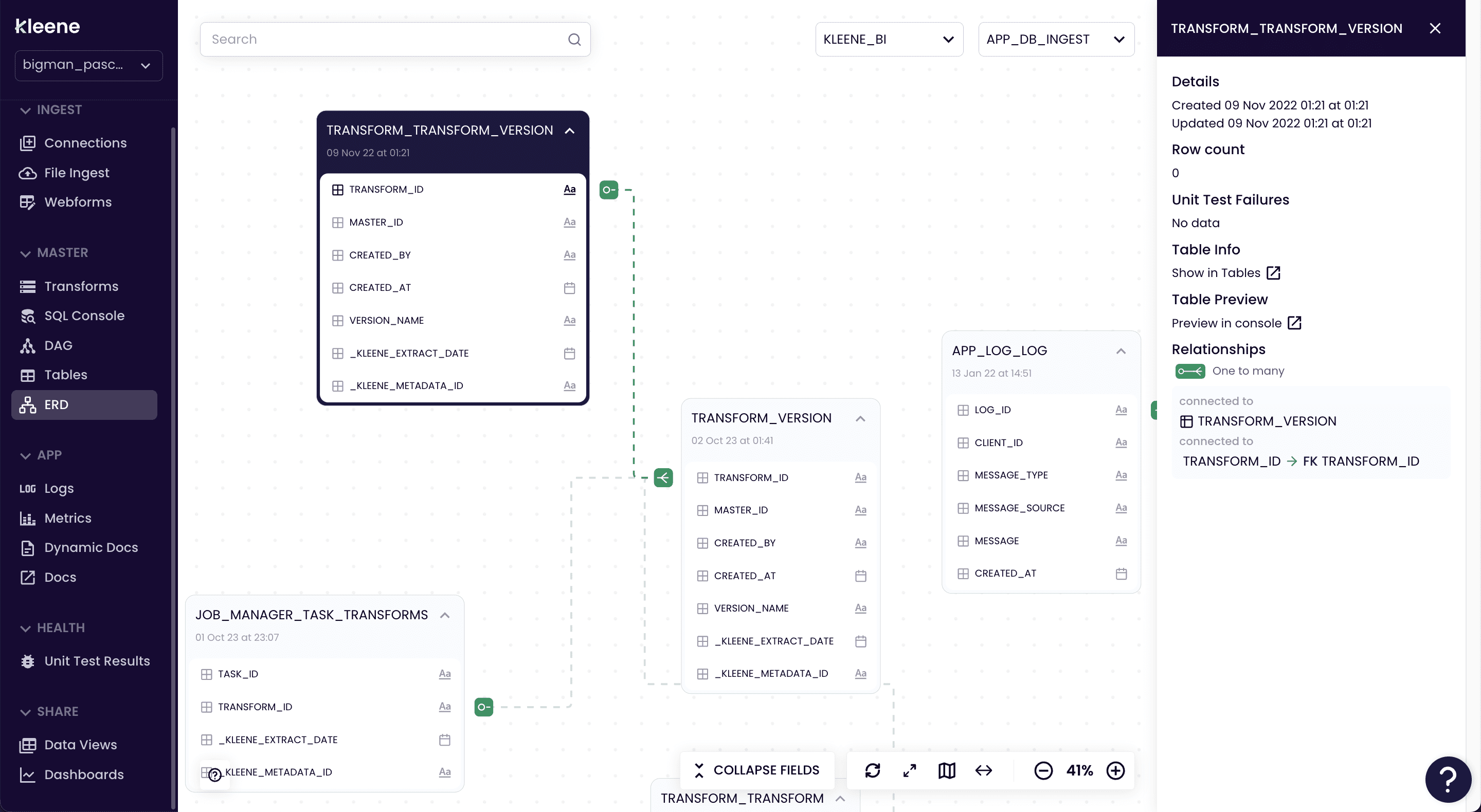

Using Kleene for Retail Inventory Management

Kleene is a leading AI-powered inventory management solution trusted by data-driven companies worldwide. With its advanced demand forecasting capabilities and comprehensive data analysis tools, Kleene gives retailers everything they need to confidently optimise inventory levels, reduce costs and improve operational efficiency. It’s a must-have platform for retail inventory management.

With Kleene’s predictive analytics and actionable insights, retailers can find new opportunities for growth around every corner. AI-powered retail inventory management offers immense potential for retailers to find ways to optimise their supply chain operations and drive enhanced customer satisfaction. In adopting a few best practices and leveraging a platform like Kleene, retailers can stay ahead of the curve.

Download our free e-book on how CFOs can master working capital in retail.

You may also like:

7 Powerful Tips for Small Business Inventory Management to Maximise Efficiency

7 Key Reasons Why a Tailored Inventory Management App Outperforms ERP Systems

7 Powerful Insights on What is Inventory in Accounting

10 Strategies for Effective Inventory Management Stock

Frequently Asked Questions

What Are Inventory Formulas?

Inventory formulas are sets of calculations used to manage inventory levels, ensuring optimal stock levels and minimizing costs.

How Can AI Improve Inventory Management?

AI enhances inventory management by providing accurate demand forecasts, real-time data processing, automated decision-making, and continuous learning.

What Are the Limitations of ERP Systems in Inventory Management?

ERP systems often have limited reporting capabilities, depend heavily on accurate data setup, and struggle with seamless integration with other systems.

How Does AI Integrate with ERP Systems?

AI integrates with ERP systems to enhance their functionality, providing comprehensive data analysis, customized reporting, and improved decision-making capabilities.

What Are the Benefits of Data Warehousing for Inventory Management?

Data warehousing provides independence from ERP data, comprehensive data analysis, and flexibility in reporting, leading to more accurate and reliable inventory management.