Breaking Down Days Inventory Outstanding: What Really Matters

Days Inventory Outstanding (DIO) tells you how long your inventory sits before being sold. While calculating DIO is straightforward, understanding how to use this metric to improve your business operations takes deeper analysis. Let’s explore how successful companies use DIO data to make smart decisions that boost their bottom line.

Why DIO Matters More Than Ever

Smart inventory management can make or break a business. DIO helps you spot potential issues before they hurt your profits. For instance, when inventory sits too long, you tie up cash that could be better used elsewhere. A fashion retailer holding last season’s styles for 80 days faces markdowns, storage costs, and lost opportunities. On the flip hand, keeping too little inventory risks stockouts and unhappy customers. Success comes from finding the right inventory level for your specific business.

Connecting DIO to Business Outcomes

Your optimal DIO changes based on market conditions and business goals. Managing this number well impacts several key areas of your business. When you reduce how long inventory sits, you cut storage costs, insurance fees, and spoilage risks. Better inventory turnover can also help you build stronger supplier relationships. By showing you can move product efficiently, you may negotiate better payment terms. This creates a positive cycle – better terms lead to even better inventory management.

Real-World Examples of DIO Success

Many companies have seen real benefits from improving their DIO. One consumer electronics retailer cut their DIO by 20% through better demand forecasting and just-in-time ordering. This freed up millions in cash they used to expand their product lines and reach new markets. In another case, a food distributor reorganized their warehouses and delivery routes to lower DIO and reduce food waste significantly. These examples show the concrete advantages of watching and improving your DIO.

From Metric to Management Tool

DIO isn’t just another spreadsheet number – it’s a powerful way to improve how your business runs and makes money. By understanding what your DIO tells you and actively managing inventory levels, you can free up cash flow, cut losses, and grow profits. You may also want to check out this guide on How to master your inventory turnover ratio for more ways to fine-tune your inventory management. These metrics work together to help you find the right approach for your business. Next, we’ll look at the nuts and bolts of calculating DIO and putting it to work in your operations.

Making DIO Calculations Work for Your Business

Now that we understand why Days Inventory Outstanding (DIO) matters, let’s explore how to calculate it properly and apply it meaningfully to your business operations. The real value comes not just from the math, but from understanding what the numbers tell you about your business performance.

Calculating DIO: Two Key Approaches

You can measure DIO using two different methods, each offering useful insights. The first method uses average inventory and cost of goods sold (COGS). Here’s a real example: Consider a company with $30 million in beginning inventory and $35 million in ending inventory. Their average inventory would be ($30 million + $35 million) / 2 = $32.5 million. With yearly COGS of $150 million, their DIO calculation would be ($32.5 million / $150 million) * 365, giving approximately 79 days.

The second method uses the inventory turnover ratio. First, calculate this ratio by dividing COGS by average inventory. Then divide 365 by that ratio to get DIO. For example, if your inventory turnover ratio is 4.6, your DIO would be 365 / 4.6 = 79 days. When done correctly, both methods should give you similar results.

Gathering the Right Data: Avoiding Common Pitfalls

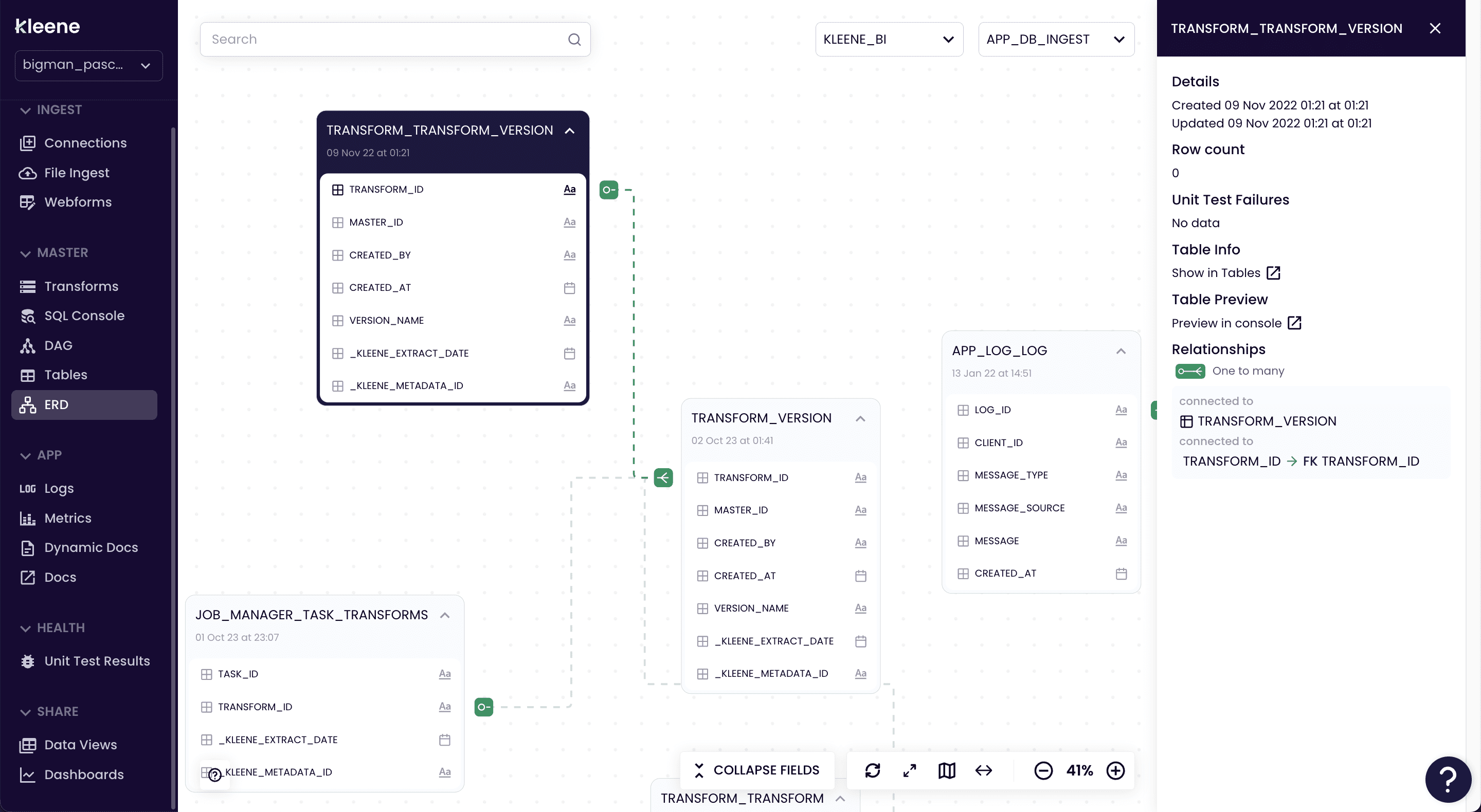

The accuracy of your DIO calculations depends heavily on clean, reliable data. Common mistakes like not accounting for damaged inventory or miscategorizing expenses can throw off your numbers significantly. For example, including obsolete stock in your inventory count inflates the average value, resulting in an artificially high DIO. Good inventory management software like Kleene.ai helps maintain accurate records. Learn more in our guide on How to master your inventory with Kleene.

Interpreting DIO: Beyond the Numbers

Reading DIO requires understanding your business context. While a low DIO often signals good inventory management and strong sales, an extremely low number might mean you’re running too lean and risking stockouts. Conversely, high DIO usually points to overstocking or slow sales. The key is finding the right balance for your specific situation, considering factors like product shelf life, seasonal demand shifts, and typical industry numbers.

Communicating DIO Insights: Driving Action

DIO serves as more than just an internal metric – it’s a powerful tool for communication with various stakeholders. When presenting to investors, DIO helps demonstrate operational efficiency. For your internal teams, DIO data can guide pricing decisions, promotional planning, and product lifecycle choices. For example, showing how reduced DIO connects to better profit margins helps team members see the direct impact of smart inventory management. This creates buy-in for data-driven decisions and shows everyone how their work affects the bottom line. By connecting DIO to concrete business outcomes, you turn abstract numbers into practical insights that drive real improvements.

Understanding Your Industry’s DIO Landscape

While calculating your company’s days inventory outstanding (DIO) is essential, the real value comes from comparing it to others in your industry. By examining how your DIO measures up against similar businesses, you can identify areas for improvement and set practical goals that make sense for your specific market.

Why Industry Benchmarks Matter

Looking at industry benchmarks helps you evaluate if your inventory performance is on track. These benchmarks show typical DIO values for businesses like yours, factoring in product categories, sales patterns, and market conditions. For instance, a 30-day DIO might be excellent for a grocery store but poor for a furniture retailer – showing why context matters so much. Studying these patterns also helps you prepare for common challenges in your sector.

Decoding DIO Variations Within Industries

Companies in the same industry often show different DIO values due to several key factors:

- Product Lifecycle: Items that sell quickly, like seasonal fashion, typically have lower DIOs than long-lasting products like appliances

- Market Dynamics: Strong demand usually leads to lower DIOs as products sell faster, while slower markets tend to have higher DIOs

- Supply Chain Complexity: Companies dealing with overseas suppliers often maintain higher DIOs because of shipping times and customs procedures, compared to those working with local vendors

Setting Realistic DIO Goals

By studying your industry’s typical DIO patterns, you can set goals that make sense for your business. Rather than chasing an arbitrary number, you can target improvements that align with industry standards while considering your unique situation. For example, if most companies in your field maintain a 60-day DIO, aiming for 45 days could be both achievable and meaningful.

Using DIO Data to Drive Strategic Decisions

Beyond simple comparison, understanding industry DIO patterns helps shape key business choices about pricing, promotions, and product development. If your DIO runs higher than average, you might create targeted sales to clear aging stock and improve cash flow. You can also learn from competitors with better DIO numbers to find practical ways to manage inventory more effectively. Success comes from regularly checking these metrics and adjusting your approach based on what you learn. The key is viewing inventory management as an ongoing process of small improvements over time.

Improving Working Capital Through Smart DIO Management

A company’s working capital – the difference between current assets and liabilities – plays a vital role in day-to-day operations. Managing days inventory outstanding (DIO) effectively is key to optimizing this working capital. By taking control of DIO, businesses can improve their financial flexibility and unlock opportunities for growth.

Understanding How DIO Affects Working Capital

The amount of cash tied up in inventory directly relates to DIO levels. When a company has high DIO, it means significant capital is sitting idle in warehouses rather than being put to productive use. For instance, a 90-day DIO indicates inventory remains unsold for three months on average – that’s three months where money could be invested elsewhere in the business. Lower DIO frees up this cash, giving companies more options to reinvest in growth, reduce debt, or maintain emergency reserves.

Practical Ways to Optimize DIO and Working Capital

Companies can use several proven approaches to reduce DIO and make better use of working capital. These methods focus on selling inventory more quickly and managing stock levels more efficiently:

- Better Demand Planning: Accurate forecasting helps avoid excess inventory by predicting future needs more precisely. This prevents cash from being tied up in slow-moving stock.

- Supply Chain Improvements: Well-run supply chains reduce delivery times and let companies operate with lower stock levels while still meeting customer needs. Just-in-time inventory is particularly effective here.

- Inventory Management Tools: Solutions like Kleene.ai provide real-time stock visibility and sales pattern insights. This helps companies adjust inventory proactively and prevent both stockouts and overstocking. You might be interested in: How to master inventory optimization with data intelligence.

- Smart Promotions: Strategic discounts can help clear slow-moving items, reducing storage costs and improving cash flow.

Finding the Right DIO Balance

While lowering DIO helps working capital, companies must ensure they keep enough stock to serve customers well. Setting DIO too low risks running out of items and losing sales. The optimal DIO varies by business and depends on factors like market conditions, industry standards, and customer needs. Getting this balance right lets companies improve their finances while keeping customers happy. Good DIO management creates a positive cycle where efficient inventory practices boost both profits and customer satisfaction.

Solving Real-World DIO Challenges

Managing your days inventory outstanding (DIO) effectively requires tackling the practical hurdles of inventory management, not just understanding formulas. From dealing with fluctuating demand to preventing obsolete stock, these day-to-day challenges can make a significant impact on your DIO metrics and overall profitability.

Managing Seasonal Demand and Supply Chain Issues

For many businesses, seasonal demand creates ongoing inventory challenges. Take a toy store, for example – they might see sales skyrocket during December only to plummet in January. This pattern can lead to either having too much stock sitting idle or running out during peak times. Both scenarios hurt DIO performance. Successfully handling these fluctuations requires accurate forecasting and flexible inventory strategies.

Supply chain problems like shipping delays or material shortages can also derail careful inventory planning. Building resilience through multiple supplier relationships and strategic safety stock helps protect against these disruptions while keeping DIO levels healthy.

Preventing Obsolete Stock and Improving Inventory Control

Stock becoming obsolete is another major DIO challenge. Products can lose value quickly due to new technology, changing customer preferences, or simple time passage. For instance, when an electronics manufacturer keeps components for discontinued models, those parts inflate DIO while tying up valuable capital. Regular inventory reviews and strategic markdowns help minimize obsolescence risk.

But improving inventory isn’t a quick fix – it requires sustained effort and commitment to getting better over time. The focus should be on creating lasting positive changes in how inventory is managed.

Creating Long-Term Inventory Excellence

Setting up successful inventory programs involves more than selecting software – it requires building a culture focused on using data to make decisions and getting everyone on board. This means helping teams understand why better DIO matters, training them on new approaches, and recognizing progress.

Tools like Kleene.ai can provide the real-time visibility needed to drive improvements. For example, showing warehouse teams how lower DIO reduces storage costs can motivate them to maintain better practices. This collaborative approach helps make inventory optimization part of daily operations rather than just a temporary project.

By addressing these real challenges through careful analysis, planning, and teamwork, companies can achieve and maintain healthy DIO levels while becoming more agile and profitable. Success comes from consistently applying best practices across the organization.

Building Your DIO Success Roadmap

Managing Days Inventory Outstanding (DIO) effectively requires more than just knowing calculations – you need a clear plan to improve inventory performance over time. In this section, we’ll explore practical strategies to optimize your DIO, from quick fixes to sustainable long-term approaches that align with your business goals.

Quick Wins for Immediate DIO Improvement

Small changes can often make a big impact on DIO metrics. Start by focusing on your bestselling products and implementing just-in-time inventory specifically for these high-demand items. This ensures you maintain enough stock to meet customer needs without excess inventory tying up capital. You can also review current stock levels to identify slow-moving items that could benefit from targeted promotions or liquidation sales. These initial improvements generate quick cash flow wins while setting the foundation for bigger changes.

Developing a Long-Term DIO Optimization Program

While quick fixes help, lasting DIO improvement needs a structured long-term strategy. Set up regular inventory reviews – monthly or quarterly – to spot trends early and adjust to market changes before they become problems. Make continuous improvement part of your process by regularly refining demand forecasts and supply chain operations. Set specific, measurable goals tied to industry standards. For example, if electronics typically sit in inventory for 70 days, aim to reduce that to 60 days within six months through focused improvements.

Building a Culture of Inventory Excellence

Success with DIO depends heavily on getting your whole team on board with data-driven inventory management. Help employees understand why DIO matters by connecting it directly to business results they care about, like higher profits and happier customers. Provide thorough training on inventory tools and processes – for instance, teaching warehouse staff better receiving methods that reduce errors and waste. When teams achieve their DIO goals, recognize and reward those wins to reinforce the importance of smart inventory practices.

Tracking Your Progress and Maintaining Momentum

Like any business initiative, measuring progress and celebrating milestones keeps everyone motivated to continue improving DIO performance. Define clear metrics aligned with your inventory goals and regularly check how you’re tracking against them. Share results across the organization to maintain engagement. Tell success stories about how better DIO management helps the business – for example, highlighting how reduced inventory costs led to more working capital for growth opportunities.

Transform your inventory management approach with Kleene.ai. Our decision intelligence platform helps you turn inventory data into clear actions that improve DIO performance and drive real business growth. Visit us today to schedule a demo and learn more about optimizing your inventory management.

Want to learn more?

Download our free e-book on how CFOs can master working capital in retail.

You may also like:

How top 1% retail CFOs are utilising AI to improve stock forecasting and impact the bottom line