Efficient inventory management is crucial for sustaining business growth and maximising profitability. Leveraging AI-powered solutions has become imperative to meeting the demands of modern retail consumers and streamlining operations. In this article, we will explore the best practices for AI-powered retail inventory management and consider how supply chain managers and CFOs can use platforms like Kleene to handle inventory.

Companies that use AI to drive decision-making outgrow their peers by 162%. This is a staggering statistic highlighting the importance of having AI-powered tools at your fingertips to outmaneuver competitors. If you are striving to offer exceptional retail experiences for customers, exploring new ways to handle and manage inventory can have a positive ripple effect across your retail business.

As a retail CFO, are you:

- Struggling with lack of visibility leading to inability to predict how to best allocate resources?

- Dealing with excess stock or stockouts due to inefficient inventory management practices that reduces working capital?

- Seeking ways to leverage AI technology to optimise inventory processes and improve profitability?

As a supply chain manager, are you:

- Struggling to manually manage the entire process using Excel?

- Dealing with manual purchase orders that drain resources and increase replenishment cycles?

- Seeking ways to reduce unnecessary stockout/overstock negatively impact revenue?

This article is for:

- CFOs in the retail industry looking to develop inventory management strategies.

- Supply chain manager looking at how to improve supply chain efficiency

- Retail executives aiming to optimise inventory levels, reduce costs and increase profitability.

- Decision-makers interested in adopting AI-powered solutions to streamline their retail operations.

Tables of Contents:

- What Is AI-Powered Retail Inventory Management?

- Best Practices In Retail Inventory Management

- 1 – Nurture Supplier Relationships

- 2 – Analyse Inventory With ABC Analysis Using AI Models

- 3 – Set KPIs (Key Performance Indicators)

- 4 – Utilise Comprehensive Data Sets

- 5 – Mitigate Risks From Market Volatility

- 6 – Manage Surplus Inventory

- 7 – Calculate Reorder Points

- 8 – Invest In Inventory Management Software

- Using Kleene for Retail Inventory Management

What Is AI-Powered Retail Inventory Management?

AI-powered retail inventory management involves the use of advanced algorithms and machine learning techniques to optimise various aspects of inventory control. This can enable retailers to forecast demand accurately, optimise stock levels, minimise costs and enhance overall operational efficiency. When retailers leverage the possibilities of AI-powered tools, they allow data to inform decision-making.

Best Practices In Retail Inventory Management

1 – Nurture Supplier Relationships

Nurturing supplier relationships is crucial for effective inventory management. Companies should look beyond transactions to cultivate strong partnerships with suppliers, fostering collaboration, trust, and reliability throughout the supply chain.

Using AI to continuously evaluate and forecast supplier performance provides insights into their reliability, quality, and delivery timelines. For instance, if a clothing retailer experiences shipment delays, AI analysis prompts proactive communication with the supplier to address the issue. According to McKinsey & Co., AI-driven forecasting can reduce supply chain errors by 20% to 50%.

Strong supplier relationships and predictive analytics enable CFOs to foresee potential challenges and mitigate risks. Benefits include preferential pricing, flexible payment terms, and access to exclusive products, all contributing to improved cost efficiency and profitability.

Building solid supplier relationships and using predictive analytics empowers supply chain managers and CFOs to optimise supply chain performance, reduce lead times, improve product quality, and enhance supply chain efficiency.

2 – Optimise Inventory Turnover

Optimizing inventory turnover is a key strategy for CFOs looking to improve operational efficiency, reduce costs, and meet customer demand without the risks associated with overstocking. Inventory turnover refers to the frequency at which a company sells and replenishes its stock over a specific period. A high inventory turnover rate is often a sign of effective inventory management, reflecting strong sales and a streamlined supply chain. It indicates that products are moving quickly, reducing the risk of holding excess stock that can lead to increased storage costs or obsolescence. Conversely, a low turnover rate can signal inefficiencies, such as overstocking or weak sales performance, which can tie up valuable capital and resources in unsold goods.

Consider the following approaches:

Deploy AI for Inventory Turnover Analysis

Use AI tools to analyse turnover rates, identifying underperforming products and bottlenecks. For example, a clothing store might find certain seasonal items moving slower than expected. AI tools can help recognise patterns early, allowing for adjustments in ordering strategy to reduce slow-moving items and focus on high-demand products.

Implement Demand-Responsive Replenishment

Establish systems that adjust to real-time demand data, ensuring inventory levels match market needs. For instance, if a style of jeans sells rapidly due to a social media endorsement, the system can automatically increase orders for that item.

Optimise Inventory Across Sales Channels

Use AI analytics to balance and optimise inventory distribution across various channels, from brick-and-mortar stores to e-commerce platforms, ensuring each has the right inventory levels to meet demand.

3 – Set KPIs (Key Performance Indicators)

KPIs serve as benchmarks for measuring the success of inventory management strategies and guiding decision-making processes. CFOs should define clear and actionable KPIs to align inventory management practices with broader organisational objectives, such as maximising profitability, optimising working capital efficiency and enhancing customer satisfaction.

These indicators can also provide visibility into critical aspects of inventory performance, such as turnover ratios, stockout rates and order fulfillment efficiency. This means that CFOs can identify areas for improvement and track progress over time. As performance metrics, KPIs drive accountability, foster continuous improvement, and ensure inventory management remains aligned with strategic goals.

CFOs can use KPIs to establish a framework for measuring the effectiveness of inventory management initiatives and assessing their impact on financial performance. As a CFO, when you define specific, measurable, and achievable KPIs, you can evaluate the success of inventory management strategies in real-time, identify trends and patterns and make data-driven decisions to optimise inventory levels.

Setting KPIs also enables CFOs to communicate performance expectations to stakeholders across the organisation, which fosters alignment and accountability at all levels. You can have KPIs cascading throughout your organisation, which will ensure that everyone is working toward common goals and driving collective success.

4 – Utilise Comprehensive Data Sets

With the possibility for vast amounts of information to be generated and collected at every touch point in the supply chain, data sets are essential for CFOs looking to optimise inventory management practices and drive financial performance. Data sets encompassing sales data, market trends, customer behaviour, can help CFOs gain valuable insights into demand patterns and identify opportunities for business growth.

For example, let’s consider Trendhim, a Denmark-based online store specialising in high-quality, affordable men’s accessories and jewellery. Trendhim faced significant challenges with forecasting accuracy and heavy manual intervention in their supply chain management. To address these issues, they implemented an AI-powered inventory management app offering advanced forecasting capabilities and customisation options tailored to their specific needs.

The primary challenge with their previous system was its inability to integrate demand signals effectively. By incorporating marketing plans and external demand signals into their forecasting model, Trendhim could better align their purchasing decisions with actual customer demand. This integration significantly reduced instances of stockouts and overstocks, resulting in improved forecasting accuracy and positively impacting their profit and loss statements. This example underscores the critical role of structured product data and data-driven decision-making in modern retail operations.

Integrating data from multiple sources, including internal systems, third-party suppliers, and external databases, enables CFOs to gain a 360-degree view of their supply chain operations. This holistic perspective helps identify inefficiencies, uncover hidden opportunities, and optimise inventory management processes.

Leveraging comprehensive data sets facilitates collaboration and knowledge sharing across functional areas within the organisation, enabling cross-functional teams to work together toward common goals and drive collective success.

5 – Mitigate Risks From Market Volatility

Market volatility can significantly impact inventory levels and supply chain operations. Some sectors are more volatile than others, but all are prone to some degree of disruption. Whether due to the political unrest and uncertainty caused by Brexit or the topsy-turvy global economies created by COVID, the war in Ukraine, and the cost-of-living crisis, businesses need to stay on the front foot to respond to shifting expectations, price rises, and market upheaval.

AI-powered forecasting models can analyse market trends and consumer behaviour to anticipate changes in demand and supply dynamics. Mitigating the risks caused by market volatility is no mean feat. It requires accurately predicting the unpredictable, keeping a close eye on market forces, adapting quickly to changing conditions, and balancing risk management with growth opportunities. When retailers proactively adjust inventory levels and supply chain strategies, they can mitigate the impact of market volatility and maintain business continuity.

Maintaining a competitive advantage (and minimising disruption to ongoing operations) during times of volatility demands substantial resources for analysis, strategy development, and implementation. While eliminating market risks completely is unlikely, applying various inventory and supplier management strategies can reduce these risks. Recent advancements in AI have also expanded the risk mitigation toolkit, providing businesses with innovative tools to navigate through uncertain times effectively.

6 – Manage Surplus Inventory

Excess inventory ties up valuable resources and can lead to increased carrying costs and markdowns. With the right demand forecasting tools, you can accurately predict future demand and optimise inventory levels to avoid overstock situations. Implementing dynamic pricing strategies and promotional campaigns is essential for retailers to liquidate surplus inventory efficiently and minimise potential losses.

Implementing dynamic pricing strategies and targeted promotional campaigns is essential for retailers to efficiently liquidate surplus inventory. When retailers strategically adjust prices based on demand fluctuations and consumer behaviour, it can stimulate sales and minimise potential losses caused by excess stock. This proactive approach not only helps reduce inventory holding costs but also supports cash flow and profitability in the long run.

7 – Calculate Reorder Points

Determining the optimal reorder point for each product is critical for preventing stockouts while limiting inventory holding costs. AI algorithms can analyse historical sales data, lead times and demand variability to calculate reorder points dynamically. Setting automated replenishment triggers based on AI-driven forecasts ensures retailers can quickly replenish inventory levels and maintain optimal stock levels.

Automating replenishment triggers based on AI-driven forecasts ensures inventory levels are quickly brought back to normal, helping maintain optimal stock levels to meet customer demand effectively. You can use technology-driven solutions for reorder point calculation to enhance inventory management accuracy, reduce operational complexities and improve overall supply chain performance.

8 – Invest In Inventory Management Software

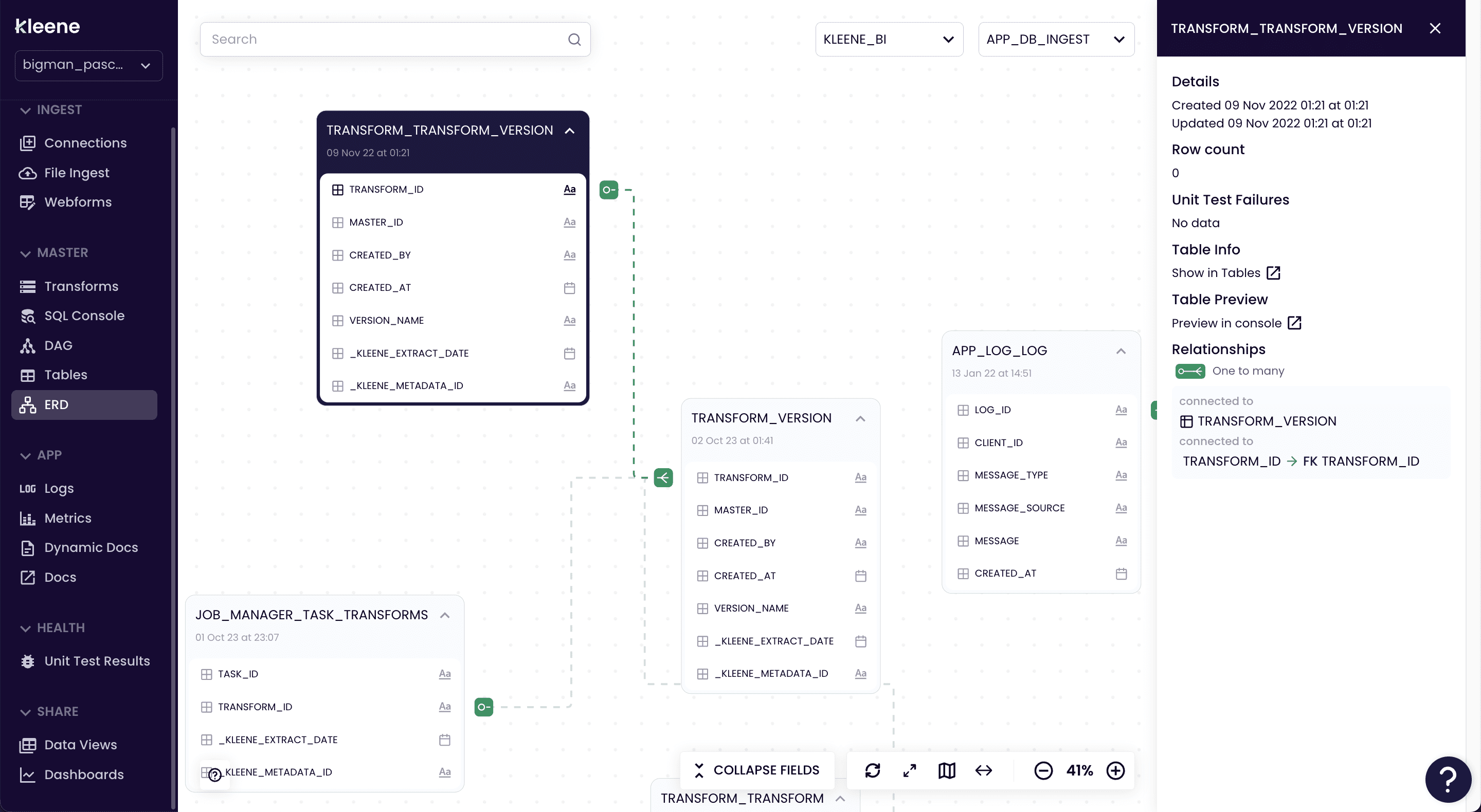

Investing in advanced inventory management software is crucial for retail businesses seeking to optimise their inventory management processes and drive business growth. With the emergence of AI-powered tools and platforms, such as Kleene, retailers now have access to a suite of sophisticated features and capabilities designed to streamline inventory management operations.

These software solutions offer features such as demand forecasting, inventory optimisation, automated replenishment and real-time analytics, giving retailers all they need to make informed decisions and respond swiftly to changing market dynamics. Using AI algorithms, retailers can enhance inventory visibility, improve stock accuracy and minimise stockouts to boost customer satisfaction and loyalty.

Advanced inventory management software enables retailers to identify trends, patterns and opportunities within their supply chain. This can help facilitate strategic planning and resource allocation. When retailers invest in technology-driven solutions, it allows them to stay ahead of the curve, drive operational efficiency, and unlock new avenues for business growth and expansion in both the near and far future.

Using Kleene for Retail Inventory Management

Kleene is a leading AI-powered inventory management solution trusted by data-driven companies worldwide. With its advanced demand forecasting capabilities and comprehensive data analysis tools, Kleene gives retailers everything they need to confidently optimise inventory levels, reduce costs and improve operational efficiency. It’s a must-have platform for retail inventory management.

With Kleene’s predictive analytics and actionable insights, retailers can find new opportunities for growth around every corner. AI-powered retail inventory management offers immense potential for retailers to find ways to optimise their supply chain operations and drive enhanced customer satisfaction. In adopting a few best practices and leveraging a platform like Kleene, retailers can stay ahead of the curve.

Download our free e-book on how CFOs can master working capital in retail.

You may also like:

How top 1% retail CFOs are utilising AI to improve stock forecasting and impact the bottom line

Retail Demand Forecasting: How CFOs Utilise AI To Optimise Working Capital