Introduction to Stock Control System

A well-functioning stock control system is crucial for any business managing inventory. It ensures optimal stock levels, prevents overstocking or stockouts, and maintains smooth operations. In this article, we’ll delve into the intricacies of stock control systems, highlighting their importance, various methods, and how integrating them with advanced data solutions can provide superior results compared to traditional ERP systems.

What is a Stock Control System?

A stock control system, also known as inventory control, refers to the process of managing, organizing, and overseeing the stock or inventory of a business. The primary goal of a stock control system is to ensure that the right amount of stock is available at the right time, minimizing costs while meeting customer demands.

Importance of Stock Control Systems

Effective stock control systems are vital for several reasons:

- Preventing Overstocks and Stockouts: By maintaining optimal stock levels, businesses can avoid the costs associated with excess inventory and the missed sales opportunities due to stockouts.

- Improving Cash Flow: Efficient stock control ensures that capital is not tied up in unsold inventory, thereby improving cash flow.

- Enhancing Customer Satisfaction: Consistently meeting customer demand without delays leads to higher customer satisfaction and loyalty.

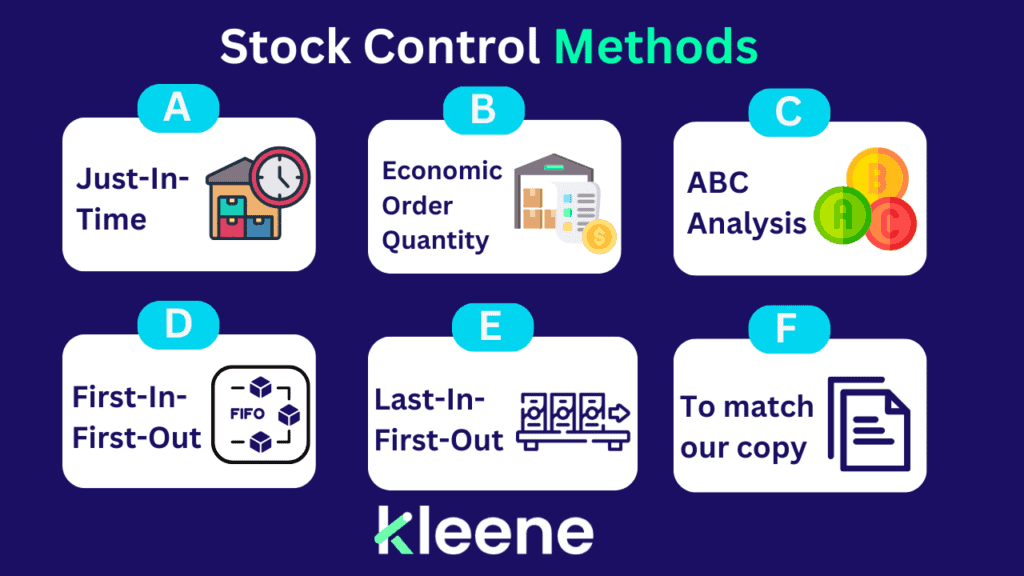

Stock Control Methods

Several methods can be employed within a stock control system to manage inventory effectively. These include:

- Just-In-Time (JIT): This method involves keeping inventory levels low and ordering stock only when needed, reducing holding costs.

- Economic Order Quantity (EOQ): EOQ calculates the optimal order quantity to minimize total inventory costs, including ordering and holding costs.

- ABC Analysis: This method categorizes inventory into three groups (A, B, and C) based on their importance and value, allowing businesses to focus on the most critical items.

- First-In-First-Out (FIFO): FIFO ensures that older stock is sold first, reducing the risk of obsolescence.

- Last-In-First-Out (LIFO): LIFO is used in certain industries where the most recently acquired inventory is sold first.

You may also like: Unlocking Success: The 10 Most Powerful Inventory Formulas

ERP Systems vs. Advanced Data Integration

ERP systems are commonly used for stock control, but they have limitations. These systems often lack the flexibility and comprehensive reporting needed for optimal stock management. Integrating stock control data into a data warehouse can address these limitations, ensuring accurate forecasts and better results.

Limitations of ERP Systems

- Limited Functionality: ERP systems may not have all the necessary features for effective stock control, requiring additional tools or manual processes.

- Dependency on Correct Setup: ERPs rely heavily on being correctly set up and maintained, which can be time-consuming and expensive.

- Restricted Reporting: Reports generated by ERP systems are often limited, making it difficult to gain detailed insights into stock control.

Benefits of Data Warehouse Integration

- Enhanced Accuracy: A data warehouse consolidates data from various sources, providing more accurate and reliable stock control information.

- Independence from ERP: By integrating data into a data warehouse, businesses are not solely dependent on their ERP systems for accurate stock control.

- Comprehensive Reporting: Tailored reports specific to a business’s needs can be generated, offering deeper insights and better decision-making capabilities.

Black-Box Solutions vs. Tailored Integrations

Using a black-box solution that sits on top of ERPs might seem like a quick fix, but it often fails to integrate seamlessly with a company’s unique tech stack, sales channels, and other systems.

Drawbacks of Black-Box Solutions

- Lack of Customization: Black-box solutions are generic and may not fit the specific requirements of a business.

- Integration Challenges: These solutions might not integrate well with existing systems, leading to data silos and inefficiencies.

- Limited Adaptability: Black-box solutions are not easily adaptable to changing business models or processes.

Advantages of Tailored Integrations

- Seamless Integration: A tailored solution is designed to fit perfectly with a company’s existing systems, ensuring smooth operations.

- Customizable Reports: Tailored integrations offer the ability to generate reports that are specific to a business’s unique needs and use cases.

- Scalability: Customized solutions can grow and evolve with the business, providing long-term value.

Conclusion

A robust stock control system is essential for effective inventory management. While ERP systems offer basic stock control functionalities, integrating data into a data warehouse provides more accurate forecasts and comprehensive reporting. Tailored integrations, as opposed to black-box solutions, ensure seamless integration with existing systems and adaptability to a business’s unique needs. By understanding and implementing the right stock control methods, businesses can optimize their inventory management, improve cash flow, and enhance customer satisfaction.

With the insights provided in this article, businesses can make informed decisions about their stock control systems, ensuring efficient and effective inventory management.

Using Kleene for Retail Inventory Management

Kleene is a leading AI-powered inventory management solution trusted by data-driven companies worldwide. With its advanced demand forecasting capabilities and comprehensive data analysis tools, Kleene gives retailers everything they need to confidently optimise inventory levels, reduce costs and improve operational efficiency. It’s a must-have platform for retail inventory management.

With Kleene’s predictive analytics and actionable insights, retailers can find new opportunities for growth around every corner. AI-powered retail inventory management offers immense potential for retailers to find ways to optimise their supply chain operations and drive enhanced customer satisfaction. In adopting a few best practices and leveraging a platform like Kleene, retailers can stay ahead of the curve.

Download our free e-book on how CFOs can master working capital in retail.

You may also like:

7 Powerful Tips for Small Business Inventory Management to Maximise Efficiency

Boost Your Inventory Turnover Ratio with These 5 Proven Strategies

7 Powerful Insights on What is Inventory in Accounting

Achieving Optimal Stock Levels: 5 Effective Strategies

10 Strategies for Effective Inventory Management Stock

Frequently Searched Questions about Stock Control Systems

To enhance the value of this article and provide comprehensive information, here are answers to some frequently searched questions about stock control systems:

What is a Stock Control System and How Does it Work?

A stock control system manages the stock levels of a business, ensuring that inventory is maintained at optimal levels. It tracks stock from the moment it is received until it is sold, providing real-time data and insights to help businesses make informed decisions.

Why is Stock Control Important?

Stock control is crucial because it helps businesses avoid overstocking or stockouts, improves cash flow, enhances customer satisfaction, and provides valuable data for strategic planning.

What are the Different Stock Control Methods?

The main stock control methods include Just-In-Time (JIT), Economic Order Quantity (EOQ), ABC Analysis, First-In-First-Out (FIFO), and Last-In-First-Out (LIFO).

How Do ERP Systems Support Stock Control?

ERP systems support stock control by providing tools to manage inventory, track stock levels, and generate reports. However, they may have limitations in terms of functionality and reporting.

What are the Limitations of ERP Systems in Stock Control?

ERP systems can be limited by their dependency on correct setup, lack of flexibility, and restricted reporting capabilities, which can hinder effective stock control.

How Can Data Warehouse Integration Improve Stock Control?

Integrating stock control data into a data warehouse can provide more accurate and reliable information, reduce dependency on ERP systems, and enable the generation of detailed, customized reports.

What is the Difference Between Black-Box Solutions and Tailored Integrations?

Black-box solutions are generic and may not integrate well with existing systems, while tailored integrations are customized to fit a business’s specific needs, ensuring seamless operations and better adaptability.

You may also like: 7 Key Reasons Why a Tailored Inventory Management App Outperforms ERP Systems