Inventory management stock is a critical component of any business that deals with physical products. Properly managing inventory ensures that stock levels are optimised, costs are controlled, and customer demands are met promptly. In this comprehensive guide, we will delve into the importance of inventory management stock, explore key techniques, and answer frequently searched questions to provide a detailed understanding of this crucial business function.

Understanding Inventory Management Stock

Inventory management stock involves overseeing the flow of goods from manufacturers to warehouses and from these facilities to points of sale. Effective inventory management stock ensures that the right amount of stock is available at the right time, reducing the costs associated with overstocking and stockouts. Businesses that master inventory management stock can significantly enhance their operational efficiency and profitability.

Key Messages

- ERP Systems are Limited: ERP systems often lack comprehensive functionalities and reporting capabilities. Integrating data into a data warehouse allows for more accurate forecasts and results, as it bypasses the limitations of ERP data setups.

- Integration with Data Warehouses: By integrating data into a data warehouse, businesses are not dependent on the ERP data being correctly set up. This integration ensures accurate forecasting and results, avoiding the time-consuming and expensive process of setting up ERP systems.

- Tailored Solutions vs. Black-Box Solutions: Black-box solutions that sit on top of ERPs may not integrate seamlessly with your tech stack, sales channels, and other systems. These solutions are not adaptable to the specific needs of your business, leading to inefficiencies and limited reporting capabilities.

Inventory Management Techniques

1. Just-In-Time (JIT)

Just-In-Time (JIT) is an inventory management stock technique where materials are ordered and received only as they are needed in the production process. This method reduces inventory holding costs and minimizes waste by reducing the amount of idle inventory. By implementing JIT, businesses can maintain a lean inventory while ensuring that materials are available when required.

2. ABC Analysis

ABC Analysis is a technique used to categorise inventory into three groups based on their value and importance. ‘A’ items are the most valuable, ‘B’ items are moderately valuable, and ‘C’ items are the least valuable. This classification helps businesses prioritize their inventory management stock efforts and focus on the most critical items. ABC Analysis can significantly improve inventory accuracy and efficiency.

3. Drop Shipping

Drop shipping is a retail fulfilment method where a store doesn’t keep the products it sells in stock. Instead, when a store sells a product, it purchases the item from a third party and has it shipped directly to the customer. This technique eliminates the need for inventory storage and reduces inventory management stock costs. It allows businesses to offer a wider range of products without the risks associated with holding large amounts of stock.

4. Bulk Shipping

Bulk shipping involves purchasing and shipping goods in large quantities. This technique can lead to significant cost savings due to economies of scale. However, it requires effective inventory management stock practices to ensure that the additional inventory does not lead to overstocking and increased holding costs. Businesses must balance the cost benefits of bulk shipping with the risks of excess inventory.

5. Safety Stock Management

Safety stock management involves maintaining a buffer of inventory to protect against uncertainties in demand and supply. Safety stock acts as a cushion to prevent stockouts during unexpected spikes in demand or delays in supply. Proper safety stock management ensures that businesses can meet customer demands consistently, even in unpredictable situations.

6. Automated Reordering

Automated reordering systems use technology to automatically reorder inventory when stock levels reach a predetermined threshold. This technique reduces the need for manual monitoring and ensures that inventory levels are maintained optimally. Automated reordering can improve efficiency and accuracy in inventory management stock, reducing the risk of stockouts and overstocking.

7. Regular Audits

Regular inventory audits are essential for maintaining accurate inventory records. These audits involve physically counting inventory and comparing it to the recorded inventory levels. Regular audits help identify discrepancies, reduce shrinkage, and ensure that the inventory management stock system reflects the actual inventory levels. Audits also help in identifying issues with inventory processes and implementing corrective measures.

8. Forecasting and Demand Planning

Accurate forecasting and demand planning are crucial for effective inventory management stock. By analysing historical sales data, market trends, and other relevant factors, businesses can predict future demand and adjust their inventory levels accordingly. Proper forecasting and demand planning help businesses avoid overstocking and stockouts, ensuring that inventory levels are aligned with customer demand.

9. Vendor-Managed Inventory (VMI)

Vendor-Managed Inventory (VMI) is a supply chain initiative where the supplier takes responsibility for managing and replenishing the buyer’s inventory. VMI can improve inventory management stock by reducing the buyer’s burden of inventory management and ensuring timely replenishment of stock. This technique fosters closer collaboration between suppliers and buyers, leading to better inventory optimisation.

10. Use of Inventory Management Software

Inventory management software provides tools for tracking, managing, and optimising inventory levels. These software solutions offer features such as real-time inventory tracking, automated reordering, and detailed reporting. Using inventory management software can significantly enhance the efficiency and accuracy of inventory management stock, providing businesses with the insights needed to make informed decisions.

ERP Systems and Their Limitations

ERP (Enterprise Resource Planning) systems are designed to manage various business processes, including inventory management stock. However, these systems often have limitations that can hinder effective inventory management. ERP systems typically provide basic inventory functionalities and may not offer detailed reporting capabilities. This limitation can result in inaccurate forecasting and inefficient inventory management.

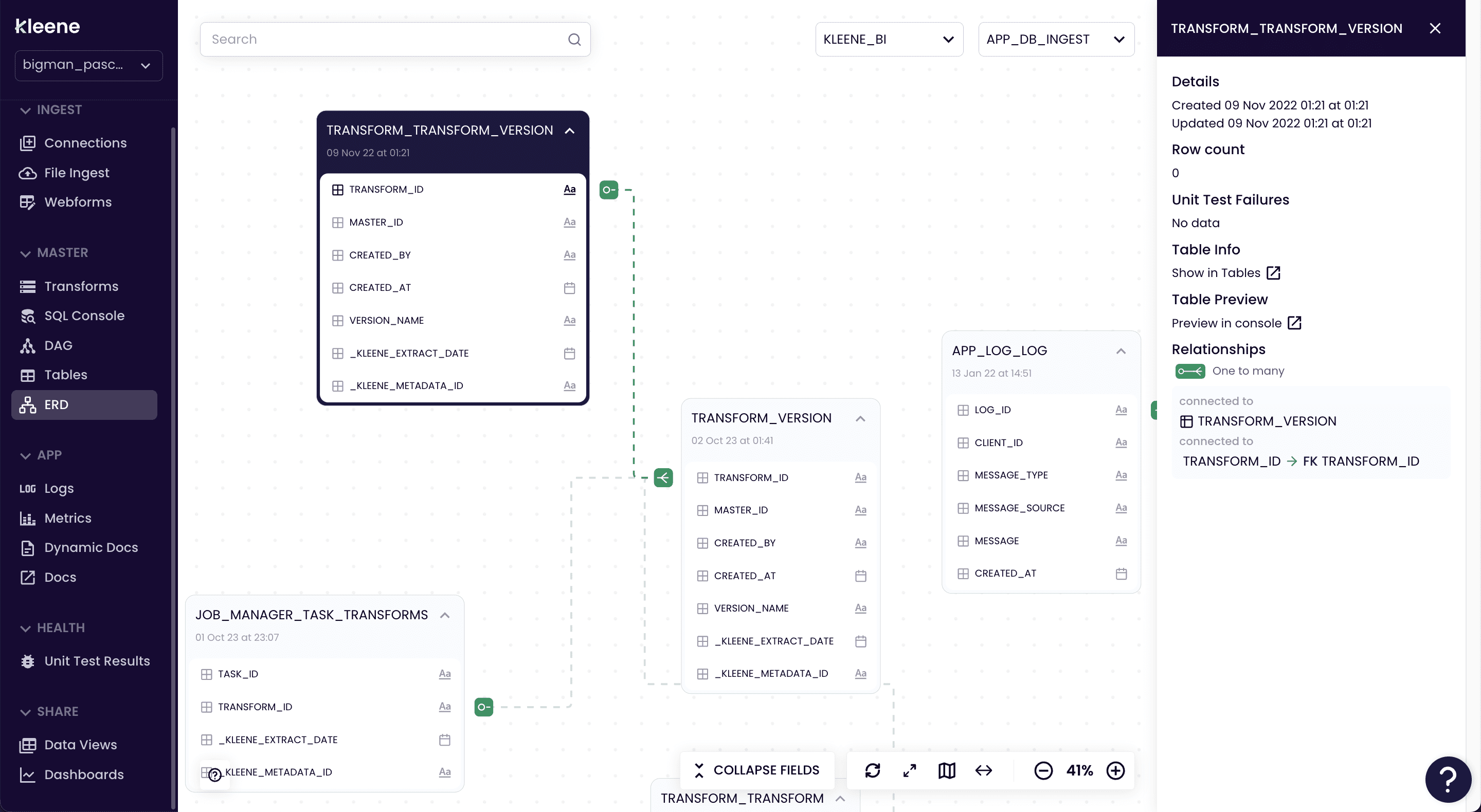

By integrating data into a data warehouse, businesses can overcome the limitations of ERP systems. A data warehouse consolidates information from various sources, providing a comprehensive view of inventory management stock. This integration allows for more accurate forecasts and better decision-making, as it leverages data from multiple systems and sources.

Integration with Data Warehouses

Integrating data into a data warehouse involves consolidating information from various business systems, including ERP, CRM, and other operational systems. This integration provides a unified view of inventory management stock, enabling businesses to make more informed decisions. Data warehouses offer several advantages for inventory management stock:

- Improved Accuracy: By consolidating data from multiple sources, data warehouses provide a more accurate and comprehensive view of inventory levels. This improved accuracy enhances forecasting and planning.

- Enhanced Reporting: Data warehouses offer advanced reporting capabilities that go beyond the basic reports provided by ERP systems. Businesses can generate detailed reports tailored to their specific needs, providing deeper insights into inventory management stock.

- Scalability: Data warehouses can handle large volumes of data, making them suitable for businesses of all sizes. As businesses grow, their inventory management stock data can be easily scaled within the data warehouse.

- Flexibility: Data warehouses can integrate with various business systems and adapt to changing business requirements. This flexibility ensures that the inventory management stock system remains relevant and effective over time.

Black-Box Solutions vs. Tailored Solutions

Black-box solutions are pre-packaged software applications that sit on top of existing ERP systems. While these solutions can provide some inventory management stock functionalities, they often lack the flexibility and customisation needed to meet specific business needs. Black-box solutions may not integrate seamlessly with other systems, leading to inefficiencies and limited reporting capabilities.

In contrast, tailored solutions are designed to fit the unique requirements of a business. These solutions offer several advantages for inventory management stock:

- Customisation: Tailored solutions can be customised to meet the specific needs of a business. This ensures that the inventory management stock system aligns with the business processes and objectives.

- Seamless Integration: Tailored solutions integrate seamlessly with existing business systems, such as ERP, CRM, and other operational systems. This integration enhances the efficiency and accuracy of inventory management stock.

- Enhanced Reporting: Tailored solutions provide detailed reports that are specific to the business’s needs. This eliminates the need for additional spreadsheets and manual data entry, improving the accuracy and efficiency of reporting.

- Adaptability: Tailored solutions can adapt to changing business requirements, ensuring that the inventory management stock system remains relevant and effective over time. This adaptability enhances the long-term value of the solution.

Conclusion

Effective inventory management stock is essential for any business that deals with physical products. By understanding and implementing the right techniques, businesses can optimise their stock levels, reduce costs, and improve overall efficiency. ERP systems, while useful, have limitations that can be overcome by integrating data into a data warehouse. Tailored solutions provide better integration and specific reporting, making them superior to standalone systems. By mastering inventory management stock, businesses can enhance their operational efficiency and profitability.

Using Kleene for Retail Inventory Management

Kleene is a leading AI-powered inventory management solution trusted by data-driven companies worldwide. With its advanced demand forecasting capabilities and comprehensive data analysis tools, Kleene gives retailers everything they need to confidently optimise inventory levels, reduce costs and improve operational efficiency. It’s a must-have platform for retail inventory management.

With Kleene’s predictive analytics and actionable insights, retailers can find new opportunities for growth around every corner. AI-powered retail inventory management offers immense potential for retailers to find ways to optimise their supply chain operations and drive enhanced customer satisfaction. In adopting a few best practices and leveraging a platform like Kleene, retailers can stay ahead of the curve.

Download our free e-book on how CFOs can master working capital in retail.

You may also like:

7 Powerful Tips for Small Business Inventory Management to Maximise Efficiency

Unlocking Success: The 10 Most Powerful Inventory Formulas

Boost Your Inventory Turnover Ratio with These 5 Proven Strategies

7 Powerful Insights on What is Inventory in Accounting

Frequently Searched Questions

What is Inventory Management System?

An inventory management system is a combination of technology and processes that oversee the monitoring and maintenance of stocked products. These systems track inventory levels, orders, sales, and deliveries, ensuring that stock is managed efficiently. Effective inventory management systems help businesses reduce costs, improve cash flow, and increase profitability.

What is Stock Control?

Stock control, also known as inventory control, involves managing the stock of a business to ensure that the right amount of inventory is available at the right time. This process includes tracking inventory orders, managing warehouse stock, and controlling the inflow and outflow of products. Effective stock control helps prevent overstocking and stockouts, ensuring that customer demands are met consistently.

What is Stock Management?

Stock management refers to the supervision of non-capitalized assets (inventory) and stock items. It involves monitoring the flow of goods from manufacturers to warehouses and from these facilities to points of sale. Effective stock management ensures that inventory levels are optimised, reducing costs and improving operational efficiency.

Explain Inventory Management

Inventory management is the process of ordering, storing, and using a company’s inventory. This includes the management of raw materials, components, and finished products, as well as warehousing and processing such items. Effective inventory management helps businesses reduce costs, improve cash flow, and increase profitability by ensuring that the right amount of inventory is available at the right time.

Inventory Management Definition

The definition of inventory management revolves around overseeing the flow of goods from manufacturers to warehouses and from these facilities to points of sale. Effective inventory management ensures that stock levels are maintained optimally, reducing the costs associated with overstocking and stockouts.

Inventory Management Meaning

The meaning of inventory management extends beyond tracking products. It involves a strategic approach to sourcing, storing, and selling inventory—both raw materials and finished goods. Effective inventory management helps businesses reduce costs, improve cash flow, and increase profitability by ensuring that the right amount of inventory is available at the right time.

Inventory Stock Control System

An inventory stock control system is a software application that helps businesses keep track of their stock levels, orders, sales, and deliveries. This system ensures that there is sufficient stock to meet customer demands without overstocking. Effective inventory stock control systems help businesses reduce costs, improve efficiency, and enhance customer satisfaction.

Inventory Stock Management

Inventory stock management is the process of overseeing and controlling the ordering, storage, and use of a company’s inventory. It includes managing raw materials, components, and finished products. Effective inventory stock management helps businesses reduce costs, improve cash flow, and increase profitability by ensuring that the right amount of inventory is available at the right time.

Stock Inventory

Stock inventory refers to the goods and materials a business holds. Managing this inventory efficiently is crucial to meet customer demands and avoid overstocking or stockouts. Effective stock inventory management helps businesses reduce costs, improve cash flow, and increase profitability by ensuring that the right amount of inventory is available at the right time.

Stock Management

Stock management involves the supervision of non-capitalized assets (inventory) and stock items. It is a component of supply chain management, monitoring the flow of goods from manufacturers to warehouses and from these facilities to points of sale. Effective stock management ensures that inventory levels are optimised, reducing costs and improving operational efficiency.

System Inventory Control

System inventory control refers to the integrated approach of managing inventory using a systematic process and tools. This ensures that inventory levels are maintained optimally, stock is tracked accurately, and reordering processes are streamlined. Effective system inventory control helps businesses reduce costs, improve efficiency, and enhance customer satisfaction.